When it comes to sheet metal fabrication, the tools you choose can greatly impact your results. In 2026, the top sheet metal roller machines promise enhanced precision and performance for both professionals and hobbyists. With features like adjustable roller spacing and improved portability, these machines cater to a variety of projects. Curious which models stand out in this competitive landscape? Let’s explore the ten best options that could elevate your metalworking experience.

Sheet Metal Roller 2 Station Metal Bender

The Sheet Metal Roller 2 Station Metal Bender is an ideal choice for professionals who demand precision and performance in metal fabrication. Its oblique bearing design allows you to bend sheets up to 100 degrees with ease. Weighing in as a lightweight, portable tool, it’s perfect for any worksite. You can bend lengths between 7mm-180mm and work with sheet thicknesses from 0.2mm to 1.0mm. For consistent results, use the height adjustable knob and imperial depth gauge. Remember to bend gently and use a straight cutting edge to avoid wrinkling. Trust this all-metal structure for durability and reliability in your projects.

Best For: Professionals in metal fabrication who require a reliable and precise tool for bending sheet metal.

Pros:

- Lightweight and portable, making it easy to transport to various job sites.

- All-metal construction ensures long-lasting durability and reliability.

- Adjustable height knob and imperial depth gauge provide accurate and consistent bending results.

Cons:

- Requires skilled operation for optimal results, which may not be suitable for beginners.

- Limited to bending lengths between 7mm-180mm, which may not accommodate larger sheets.

- Potential for wrinkling if not used with care, particularly during 90° bends.

VEVOR Slip Roll Machine (24-Inch Forming Width, 16 Gauge Capacity)

For those seeking a reliable and efficient tool for bending sheet metal, the VEVOR Slip Roll Machine stands out with its impressive 24-inch forming width and 16-gauge capacity. This hand-powered machine is perfect for working with aluminum alloy, low carbon steel, and copper sheets. Its upgraded roller surface minimizes friction and scratching, while detachable rollers guarantee quick access for part removal. With a reinforced base, you’ll experience stability and vibration-free operation, enhancing your results. Although it has a customer rating of 3.4 stars, its user-friendly design and performance make it a solid choice for any metalworking project.

Best For: The VEVOR Slip Roll Machine is best for hobbyists and small-scale metalworkers who need a reliable tool for bending sheet metal with ease.

Pros:

- User-Friendly Design: Easy to install and operate, making it accessible for beginners and professionals alike.

- Stable Performance: The reinforced base ensures smooth rolling without vibrations, enhancing overall results.

- Versatile Material Compatibility: Suitable for working with a variety of metals, including aluminum alloy, low carbon steel, and copper sheets.

Cons:

- Customer Rating: It has a moderate customer rating of 3.4 out of 5 stars, indicating mixed reviews.

- Hand-Powered: Being hand-powered may not be suitable for those looking for a more automated solution.

- Weight: At 84.4 pounds, it may be cumbersome for some users to move or reposition easily.

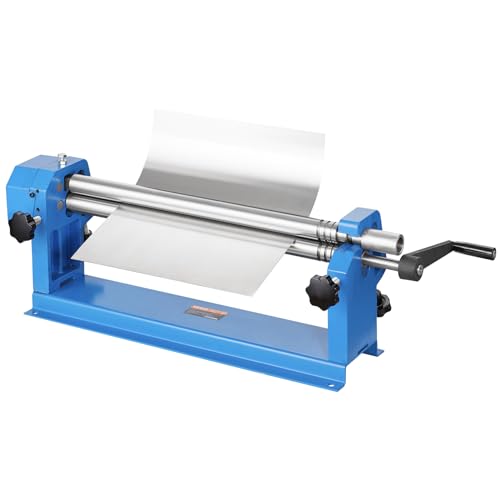

VEVOR Slip Roller Sheet Metal Rolling Bending Machine

Looking for a reliable sheet metal roller that combines precision and ease of use? The VEVOR Slip Roller Sheet Metal Rolling Bending Machine is an excellent choice. With a capacity of 20 gauge and a roller width of 12.6 inches, it handles various materials like aluminum and low-carbon steel. Weighing just 24.1 pounds, its durable steel construction guarantees stability. The adjustable knobs allow you to fine-tune roller spacing for different thicknesses. Plus, its compact design makes it easy to mount on your workbench. Enjoy shaping conical materials effortlessly with this versatile and efficient tool.

Best For: Hobbyists and professionals looking for a versatile and compact sheet metal roller suitable for various materials.

Pros:

- Durable construction with precision-ground steel rollers ensures stability and longevity.

- Adjustable knobs allow for fine-tuning roller spacing, accommodating different material thicknesses.

- Compact design makes it easy to mount on a workbench, saving space while providing powerful operation.

Cons:

- Limited to a maximum sheet thickness of 1.0 mm, which may not be suitable for thicker materials.

- Weighing 24.1 pounds, it may be challenging to move for some users.

- Mixed customer reviews, indicating variability in satisfaction and performance.

VEVOR Jewelry Press, 3-in-1 Functionality

Crafting intricate metal jewelry becomes a breeze with the VEVOR Jewelry Press, designed specifically for jewelry professionals and DIY enthusiasts alike. This versatile 3-in-1 machine lets you transform gold, silver, and other malleable metals into thin sheets, square wires, and half-round shapes. With a gear ratio of 1:2, you can easily adjust the press thickness from 0.03 to 6.5mm for precise results. Its CNC-machined gears guarantee high accuracy, while the durable 45# steel rollers provide exceptional wear resistance. The rust-resistant coating and heat-treated body assure longevity, making it an essential tool for your jewelry-making projects.

Best For: Jewelry professionals and DIY enthusiasts looking to craft intricate metal pieces with precision and ease.

Pros:

- High-quality 45# steel rollers ensure exceptional durability and a smooth finish.

- Adjustable thickness from 0.03 to 6.5mm allows for versatile crafting options.

- CNC-machined gears provide high accuracy for precise metal shaping.

Cons:

- May require some initial setup and adjustment for optimal use.

- Heavier construction could make it less portable for some users.

- Limited to malleable metals, which may restrict material choices.

VEVOR Rolling Mill Machine for Jewelry Making

The VEVOR Rolling Mill Machine stands out as an excellent choice for jewelry professionals and DIY enthusiasts alike, thanks to its impressive 1:2 gear ratio and the ability to handle materials like gold, silver, and copper. With adjustable precision thickness from 0 to 5.5 mm, you’ll enjoy CNC-machined gears that guarantee high accuracy. The durable 45# steel rollers provide exceptional wear resistance, while the rust-resistant oil treatment protects your investment. Weighing 45.19 pounds and measuring 18.9 x 5.12 x 13.39 inches, this machine is perfect for crafting various jewelry items and has received positive feedback from users.

Best For: Jewelry professionals and DIY enthusiasts looking for a reliable and versatile rolling mill for metalworking.

Pros:

- Adjustable precision thickness allows for customized roller spacing from 0 to 5.5 mm.

- Durable 45# steel rollers ensure exceptional wear resistance and high hardness.

- Suitable for a variety of malleable metals, making it versatile for crafting different jewelry items.

Cons:

- Weighs 45.19 pounds, which may make it less portable.

- Dimensions may require a dedicated workspace for setup and use.

- Limited to malleable metals, excluding harder materials.

Roller Bender Manual Plate Steel Ring Bender

For those seeking an eco-friendly and efficient solution for bending metal, the Roller Bender Manual Plate Steel Ring Bender stands out as an excellent choice. This heavy-duty, compact tool operates without electricity, saving you energy costs while bending flat and round stock. With the ability to bend solid flat steel up to 2.25 inches wide and 0.18 inches thick, it’s perfect for various projects, from industrial production to DIY home decor. Its user-friendly design makes it accessible for everyone, allowing quick and precise circle creation. Plus, its portable structure guarantees you can easily transport it to any worksite.

Best For: Those looking for an eco-friendly and user-friendly solution for bending metal, ideal for both DIY enthusiasts and professionals.

Pros:

- Operates without electricity, providing an eco-friendly and cost-effective option.

- User-friendly design allows for quick setup and operation, suitable for all skill levels.

- Portable structure makes it easy to transport to various work sites.

Cons:

- Manual operation may require more physical effort compared to electric alternatives.

- Limited bending capacity may not be suitable for larger projects or thicker materials.

- Learning curve for beginners who may need practice to achieve perfect bends.

Sheet Metal Roller 2 Station Metal Bender

Engineered for professionals in metal roofing and sheet metal fabrication, the Sheet Metal Roller 2 Station Metal Bender stands out with its lightweight, portable design and impressive bending range of 0-100°. You’ll appreciate its oblique bearing design, preventing scratches while achieving clean 90° bends. This tool handles bending lengths from 7mm to 180mm and accommodates sheet thicknesses between 0.2mm and 1.0mm. For ideal results, bend gently, moving back and forth 5 to 8 times. Made from durable all-metal materials, it guarantees longevity, while the aluminum grip and stainless steel rollers enhance performance. Follow usage tips for consistent, effective results.

Best For: Professionals in metal roofing and sheet metal fabrication looking for a portable and efficient bending tool.

Pros:

- Lightweight and highly portable design for easy transportation and use.

- Oblique bearing design prevents material scratches while allowing for precise bends.

- Durable construction with all-metal materials ensures long-lasting performance.

Cons:

- Limited bending range for thicker materials, accommodating only up to 1.0mm thickness.

- Requires careful technique to avoid material wrinkling during bends.

- May not be suitable for very large or heavy-duty metal bending tasks.

Sheet Metal Bead Roller Machine with 6 Dies Set

Designed for professionals in sheet metal processing and the automotive industry, the Sheet Metal Bead Roller Machine with a 6 Dies Set stands out with its manual crank operation. You’ll appreciate the control it offers, allowing you to manage strength and speed safely. This machine features a throat cast iron head roll and a lightweight structure, making it easy to center and operate. With a roller center distance of 50mm and a sheet thickness capacity of 1.2mm, it’s versatile for various projects. The included six molding roll sets guarantee you can achieve precise bends quickly, reducing your overall working time.

Best For: Professionals in sheet metal processing and the automotive industry seeking a manual machine with precise control.

Pros:

- User-controlled strength and speed for safer operation compared to electric motor types.

- Lightweight and simple structure allows for easy centering and operation.

- Versatile with six molding roll sets for achieving precise bends efficiently.

Cons:

- Manual operation may require more physical effort compared to electric alternatives.

- Limited to a sheet thickness of 1.2mm, which may not suit all applications.

- May require additional fixtures or table installations for optimal use.

Sheet Metal Roller 1 Station Metal Bender

The Sheet Metal Roller 1 Station Metal Bender stands out as the perfect tool for professionals who need precision in bending metal panels. With a bending range of 0-100°, it’s lightweight and portable, making it easy to set up anywhere. The oblique bearing design and exclusive angled roller guarantee you get clean 90° bends without scratching. Designed for metal panel profiling, it handles lengths from 7mm to 130mm and iron sheet thicknesses of 0.2mm-0.8mm. For ideal performance, remember to press down gently and bend gradually. Its all-metal structure guarantees durability, making it a reliable choice for your projects.

Best For: Professionals seeking a reliable and precise tool for bending metal panels in various applications.

Pros:

- Quick setup and lightweight design enhance portability and ease of use.

- Oblique bearing design and angled roller ensure clean 90° bends without scratching.

- Durable all-metal structure with high-quality materials guarantees long-lasting performance.

Cons:

- Limited bending range of 0-100° may not meet all bending needs.

- Requires skill and technique for optimal performance, which might be a learning curve for some users.

- Compatibility is restricted to specific iron sheet thicknesses (0.2mm-0.8mm), limiting material options.

Sheet Metal Roller Metal Bender (0-100° Bending Range)

For professionals who demand precision in metal bending, the Sheet Metal Roller Metal Bender with a 0-100° bending range stands out as an essential tool. It’s lightweight and portable, making it perfect for on-site jobs. The oblique bearing design guarantees you can achieve accurate bends without scratching your material, especially important for 90° angles. You’ll appreciate the height-adjustable knob and precise depth gauge for consistent results. This bender handles lengths from 7mm to 130mm and thicknesses of 0.2mm to 0.8mm. With durable, all-metal construction, it promises long-lasting performance, supporting your metal roofing and fabrication needs effectively.

Best For: Professionals in metal roofing and sheet metal fabrication seeking a portable and precise bending tool for up to 100° angles.

Pros:

- Lightweight and portable design makes it ideal for on-site jobs.

- Oblique bearing design prevents material scratches, ensuring clean 90° bends.

- Durable all-metal construction guarantees long service life even with repeated use.

Cons:

- Limited to bending lengths between 7mm and 130mm, which may not suit all projects.

- Requires technique and multiple gentle presses for accuracy, particularly for precise 90° bends.

- May not be suitable for thicker materials beyond 0.8mm, limiting its versatility.

Factors to Consider When Choosing a Sheet Metal Roller Machine

When choosing a sheet metal roller machine, you’ll want to take into account several key factors. Bending capacity, material compatibility, and durability all play a vital role in ensuring you get the best performance for your needs. Don’t forget about user-friendliness and portability, as these features can make a significant difference in your overall experience.

Bending Capacity Specifications

Bending capacity is a essential aspect to evaluate in a sheet metal roller machine, as it directly impacts your project’s feasibility and outcome. When you select a machine, consider its specifications for sheet thickness and length; many can handle thicknesses from 0.2mm to 1.0mm and lengths between 7mm and 180mm. Check the maximum bending angle, with options reaching up to 100 degrees for versatile shaping. Some machines excel with specific thickness capacities, like 16 gauge, which is important for your needs. Additionally, roller width matters—larger widths, such as 24 inches, enhance versatility. Finally, look for designs with precision adjustments, like height-adjustable knobs and depth gauges, for achieving accurate bends and consistent results in your work.

Material Compatibility Options

Choosing the right sheet metal roller machine hinges on understanding the material compatibility, as different machines are designed to handle specific metals. You’ll want to take into account whether the machine can accommodate aluminum alloy, low carbon steel, or copper sheets, as this varies greatly between models. Pay attention to the thickness capabilities; some machines manage materials up to 1.0 mm (22 gauge). Also, note the bending lengths, which can range from 7mm to 320mm. High-quality roller construction, like stainless steel or precision-ground steel, influences performance. Finally, if a machine features adjustable roller spacing, you’ll find it easier to customize the bending process for various thicknesses and types of metal, enhancing versatility in your projects.

Durability and Construction Quality

Durability and construction quality are essential factors that directly impact the performance and longevity of a sheet metal roller machine. When choosing a machine, look for all-metal structures, as they provide greater longevity and resistance to wear compared to plastic components. High-quality aluminum alloy grips and stainless steel rollers enhance durability and corrosion resistance, ensuring a longer service life. A heavy-duty design, often utilizing precision lathes, adds stability for various bending tasks. Additionally, reinforced bases made from thickened steel help prevent vibrations, ensuring smooth operation. Remember, regular maintenance and proper usage techniques are vital; improper handling can lead to premature wear or damage to critical components, affecting the machine’s overall durability and effectiveness.

User-Friendliness and Operation

When selecting a sheet metal roller machine, user-friendliness plays an essential role in ensuring a smooth operation, especially for those who may not have extensive technical expertise. Look for machines with easy installation and operation, allowing you to set up quickly. Hand-powered designs offer greater control over rolling speed and strength, simplifying the process. Adjustable features, like knobs for fine-tuning roller spacing, give you precise control over the rolling radius for varying sheet thicknesses. Clear operation instructions and simple controls are vital, ensuring users of all skill levels can effectively operate the machine. Choosing compact and portable designs makes transportation and setup easier, further enhancing your overall experience while working with metal sheets.

Portability and Storage Features

Portability and storage are essential factors to take into account in a sheet metal roller machine, especially if you frequently move between job sites. When choosing a machine, consider its weight; lightweight models are easier to transport and store. Opt for machines with a compact design that can fit into smaller workshops or garages. Look for features like detachable components that allow for easy disassembly, making transport a breeze. A lightweight and portable machine can be set up quickly, letting you maximize efficiency without extensive setup time. Also, check for handles or grips that enhance maneuverability, ensuring you can easily move the machine between locations without hassle. These features can greatly improve your overall experience.

Design and Adjustment Mechanisms

Choosing the right design and adjustment mechanisms in a sheet metal roller machine can make all the difference in your metalworking tasks. Look for features like oblique bearing systems and angled rollers that minimize scratches during 90° bends. Height-adjustable knobs and precise depth gauges guarantee accuracy for various sheet metal thicknesses and lengths. You’ll appreciate machines with quick-detach rollers for easier maintenance and adjustments, boosting your overall efficiency. Compact and portable designs allow for convenient mounting on workbenches, making it easier to adapt to different job sites. Finally, adjustable roller spacing is vital for accommodating diverse material thicknesses, enhancing the versatility of your roller machine. Prioritize these factors to optimize your metalworking experience.